My contribution to FAIR

After successfully automating the HOOS units, I was given the opportunity to enhance and expand the FAIR project with custom-made hardware and IoT/Industry 4.0 software modules. In March 2019, I began visiting various OMV Petrom locations across Romania to study different equipment that required monitoring solutions. Depending on the specifics of each piece of equipment, I have designed several types of custom-made computers tailored to their needs.

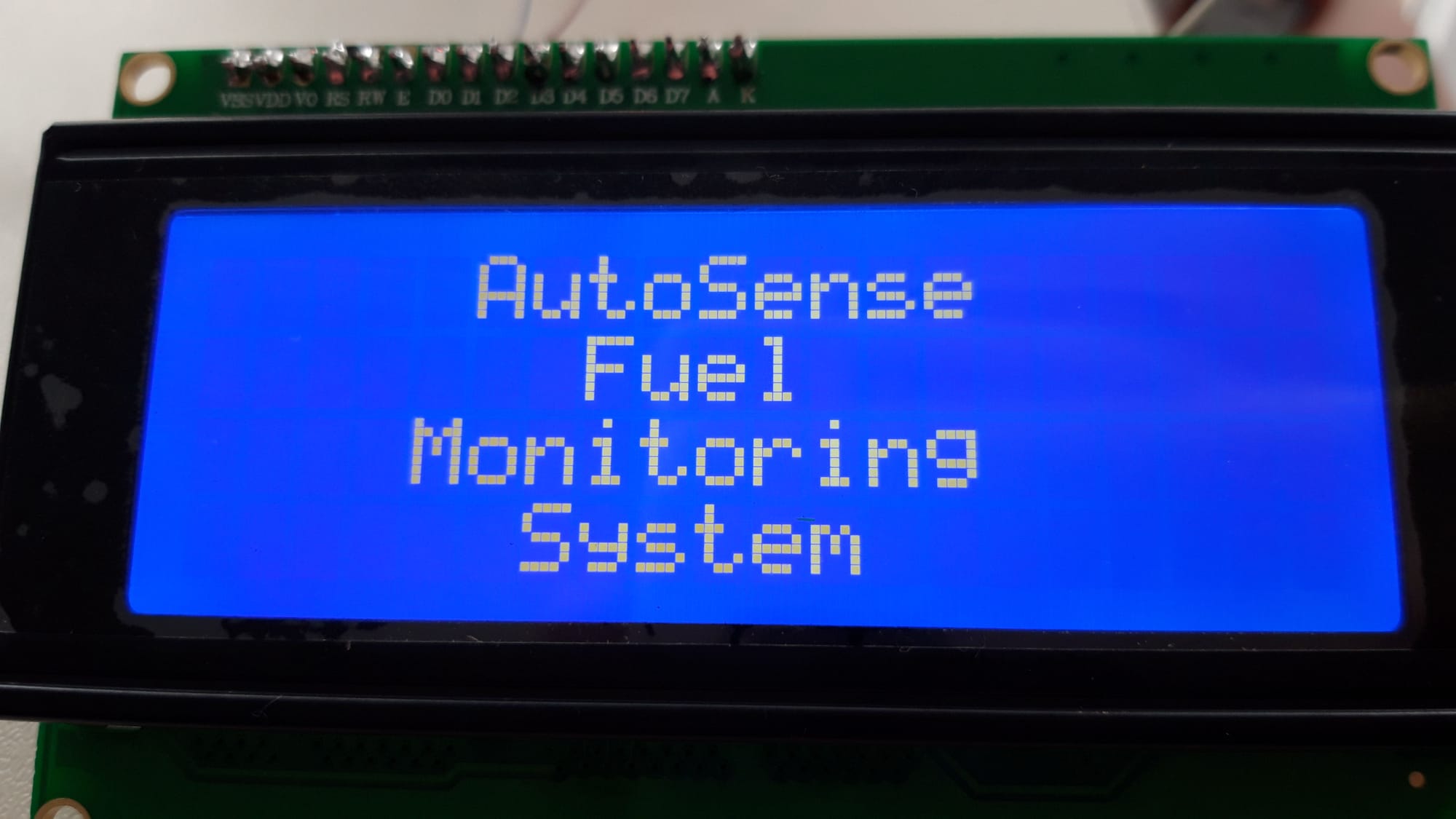

By April 2019, I had built the first pilot system for a fuel unloading station, akin to a gas station, to test its functionality under real-world conditions. This pilot system marked a significant milestone, allowing me to gather invaluable data and insights. By September 2019, I had successfully installed the monitoring system, which laid the groundwork for subsequent pilot tests on other equipment with varying functionalities.

Following the initial installation, I conducted further pilot tests on different types of equipment to ensure the robustness and reliability of this solutions. These pilot tests demonstrated the system's versatility and adaptability to different operational environments. The custom-made computers designed for these applications have proven to be highly reliable and have been functioning effectively up to the present day.

The equipment specifications include 4-8 GB of RAM, a quad-core processor, 4G mobile data communication, GPS, and IMU. They also feature interfaces for various industrial protocols, RFID cards, and power protection, filtration, and stabilization. Additionally, the software modules are highly flexible and adaptable, tailored to meet the specific needs of clients. This comprehensive approach has enabled me to deliver a robust, reliable, and scalable fuel monitoring system that addresses the unique challenges of each installation site.